AVDB is committed to the quality of its products !

For over 10 years, we have been committed to providing you with quality products and accessories. Today, we are taking things to the next level : we are proud to announce that our first AVDB products are ABE-certified !

A look back at the AVDB quality process

It's no secret that when we talk about product quality, we think first and foremost of German rigour and intransigence. So to offer you the very best, we have decided to launch a homologation process for our parts in order to obtain ABE certification. And yes, at AVDB, when we are committed to quality, we do not do things by halves!

But beware, getting ABE certification is not as easy as it looks! Are you ready for it? Because you are going to have to hang in there!

First step : register with the KBA

The KBA is no more and no less than the German Federal Motor Transport Office. It, and it alone, can approve vehicles, components and technical parts in Germany. And you can take our word for it : the KBA has to be earned! The prerequisite is a fairly thorough initial assessment, during which you have to show your credentials and provide a multitude of documents, some of which are completed jointly with our partner factories. A lot of paperwork, all in German! Add to that the vagaries of COVID, which meant that processing times were extended (and in fact some of the initial documents were obsolete because they were signed a long time ago and had to be redone), and believe us, it was anything but a walk in the park! A fairly lengthy process, since it was launched in 2019, to tell you the truth.

Step 2 : a drastic TUV audit

Quality certification is the ultimate goal of this whole process. And it's not all paperwork.

Compliance with product quality also means compliance with the company's processes for ensuring the quality of its products, from manufacture to marketing. To achieve this, we needed time to present our most complete quality process.

When we reach this stage, the TUV (Technical Inspection Association), an independent body, is commissioned to audit the company and validate that the company's internal processes comply with their requirements.

During this audit, the company's various divisions are scrutinised so that TUV can ensure that the quality management system within the company as a whole is coherent and optimal, in order to ensure the company's long-term stability while offering customers quality products and services.

At the end of the audit, the auditor submits a report to the KBA, which either approves or rejects the company's registration with the KBA. Without it, it was impossible for us to get our parts approved by TUV and to obtain ABE certification, the Holy Grail when it comes to parts quality and safety.

Not to mention the high costs involved in these initial steps, which only constitute preliminary registration with the KBA, but you already have an idea of the obstacle course you have to go through, because it is only once a company has been registered with the KBA that you can apply for ABE approval for the products you want to register!

Step 3 : obtain ABE certification

That is it, we are finally at the last step before obtaining ABE approval. Once registered with the KBA, it is also the TUV that carries out the inspections and tests on each of the parts to be approved, to ensure that they comply with the regulations and standards in place.

ABE Certification is the official document issued by the KBA but delivered by TUV, which authorises the legal use of a part or accessory on a specific motorbike in Germany. It indicates that the part in question has undergone rigorous and strict testing to ensure that it meets the required safety and performance standards.

This certification guarantees a number of advantages for all approved products :

Compatibility and adaptability of the part in accordance with the OEM part

Maximum safety

Quality and durability

Legal compliance and European compatibility

To do this, you have to provide the TUV with every reference of the original parts and of our parts so that the various comparative technical tests can be carried out on each of them and their conformity validated. It is also a long and costly process, but essential to finalise the homologation process!

Our first certified parts !

Today, we are proud to announce that our first products are officially ABE-certified !

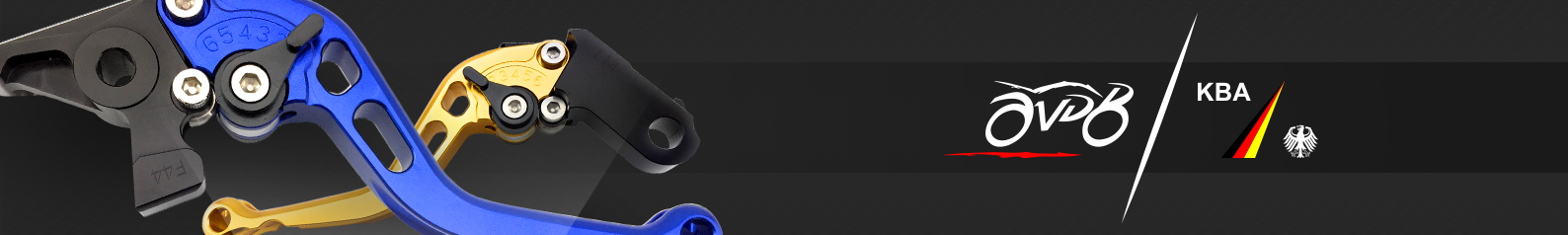

And we're not just talking about any part, because we are talking about our levers!

A long-standing feature of the AVDB catalogue, from the short and long models to the recently completely redesigned version with UNIK levers, these emblematic parts deserved to be ABE approved.

As mentioned above, and if you have managed to follow this far, it was the TUV, an independent organisation, that gave us this approval.

After supplying them with the manufacturing plans and the various models of the parts, they put them through countless tests, each more stringent and rigorous than the last.

But as yet, not all our levers are certified. As you probably know, levers are made up of 2 main parts : the body of the lever, i.e. the main part on which the fingers are placed, which is a universal part for different models of motorbike, and the adaptor, which is specific to each model of master cylinder !

Today, all our lever bodies are ABE certified !

As for the adaptors, we are in the process of getting them approved. Obviously, the procedure is longer, since each reference has to be examined with a fine-tooth comb, and when we talk about each reference, we are talking about fifty or so parts !

To be more precise, more than 400 motorbike models can already be fitted with ABE-approved AVDB and UNIK levers, and several thousand more will soon follow !

Stay tuned !

Our levers are just the first step! A number of parts will follow the same path to homologation, it is only a matter of time. We will keep you informed as and when the approvals come through, of course.

Validating this certification process is an important step, but it's only part of our commitment to quality.

We still have a long way to go to certify all our products, but the passion for quality and the demand for precision will not leave AVDB, not until we have reached our destination.